Pavilion CIRCL

Amsterdam, Netherlands

- Time

- 2016 - 2017

- Building type

- Pavilion

- Client

- ABN AMRO

- Architect

- de Architekten Cie

- Project Partners

- TU Delft, BAM, VRK, Donkergroen, DoepelStrijkers, ABN AMRO, New Horizon

- Size

- 3350 m2

- Use

- Mixed use (conference, offices, restaurant)

- Website

- Link ↗

- Banner Image

- ABN AMRO / Ossip van Duivenbode

General description

The ‘Circl pavilion’ is located in Amsterdam near Zuid station, directly in front of ABN AMRO’s main building. The bank uses the pavilion predominantly for meetings. From an urban perspective, it completes the ‘Berlage axis’, an open space connecting the station with the city. A striking element is the large glass facade opening to Gustav Mahler square. The public can use the broad steps at the side of the pavilion to reach the rooftop garden that also has a bar. Circl has over 2000m2 of meeting and work spaces and a restaurant on the ground floor.

We hope that everyone will use the new knowledge and experience we have gained through the circular construction of this building. That’s why we don’t refer to what we’ve done at Circl as ‘copyright’ but rather as right to copy.

Circl Website

Introduction to Circularity

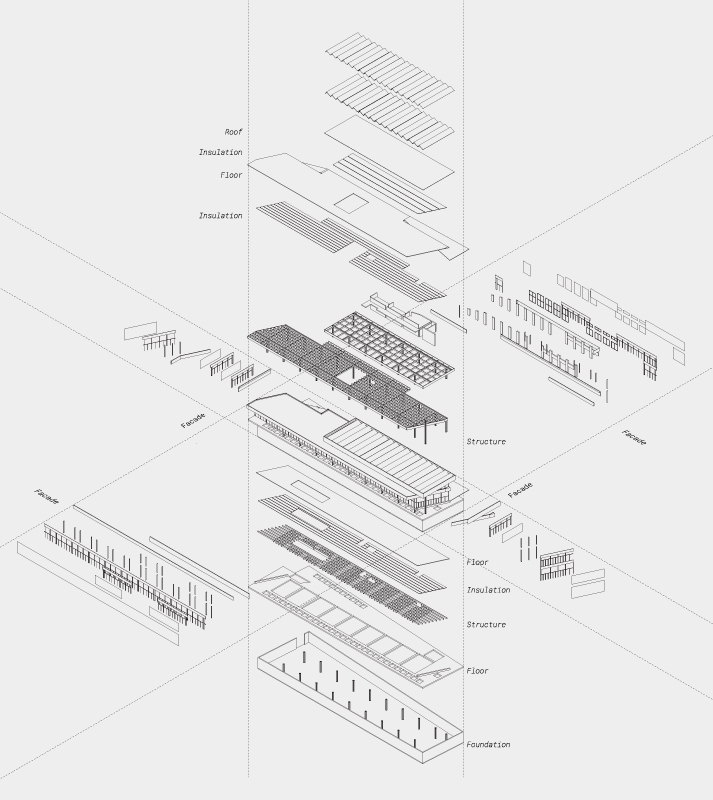

Initially, the pavilion was intended to be a modern space for conference meetings and offices but the bank’s project team was not satisfied with the level of sustainability the original design had foreseen. With the concrete foundation already in place and the program already being defined, new partners were found to create a new design that was based on circular principles. At the same time, this building became a learning platform for circular construction. From the wooden frame and beams to the glass façade and the pavement stones: everything was designed for disassembly. No unnecessary layers or wet bonding agents were used and all wood and plastic used on the project was recycled. Additionally, the project including a restaurant, rooftop garden and greenery on the facade contribute to the sustainability of the building.

Practices

We want to persuade society to move towards a sustainable world by demonstrating the changes needed to create the circular economy, both in theory and in practice. In other words, thinking big by starting small. For everyone who doesn’t just want to talk about the circular economy but wants to start building it now, in whatever capacity (…).

Circl Website

It was important to the architects that as much as possible is screwed, bolted, or clamped together, as this means easy dismantling for future reuse. From the wood frame and beams, to the glass facade and the pavement stones: everything is designed for disassembly. Also, any unnecessary layers and ‘wet’ bonding agents were avoided where possible to enable the reuse and recycling of the material. This means that the foundation was the basement floor and the walls did not receive a finishing plaster. For example, the frame consists of large larch wood beams screwed together and left unpainted. Larch is a very durable wood that lasts hundreds of years. The exterior facade is made of 55 panels of glass, designed for dis- and reassembly with aluminium window frames, which were not given a protective coat, so that the material can be melted down better. The court was paved with Belgian cobblestones that had been given a second life and are easy to dismantle and reuse again.

A colleague in the field of circular architecture, Thomas Rau, preaches the idea of renting certain building parts from the manufacturer, instead of buying them. For example, the elevator in the CIRCL Pavilion is owned by Mitsubishi and ABN AMRO pays them per vertical ride, according to the manufacturer this elevator has a longer lifespan than average lifts.

Solar panels create electricity that flows into the local grid, geo-thermal heating coils provide warm water and phase changing materials act as a temperature buffer. The solar panels installed on the roof and walls produce direct current that can be used within the building for charging electronic devices or the LED lights, minimising the need for adapters and inverters that usually change the alternate current from general electricity networks to a direct one. The panels themselves are designed and manufactured in the Netherlands and because of its additional glass layer, they last longer. Underfloor heating, connected horizontally and vertically by coils, heat water naturally and distributes it. The greenery on the roof and facade of the building protects it from sun and the evaporating water from plants cools the city’s climate.

Solar panels create electricity that flows into the local grid, geo-thermal heating coils provide warm water and phase changing materials act as a temperature buffer. The solar panels installed on the roof and walls produce direct current that can be used within the building for charging electronic devices or the LED lights, minimising the need for adapters and inverters that usually change the alternate current from general electricity networks to a direct one. The panels themselves are designed and manufactured in the Netherlands and because of its additional glass layer, they last longer. Underfloor heating, connected horizontally and vertically by coils, heat water naturally and distributes it. The greenery on the roof and facade of the building protects it from sun and the evaporating water from plants cools the city’s climate.

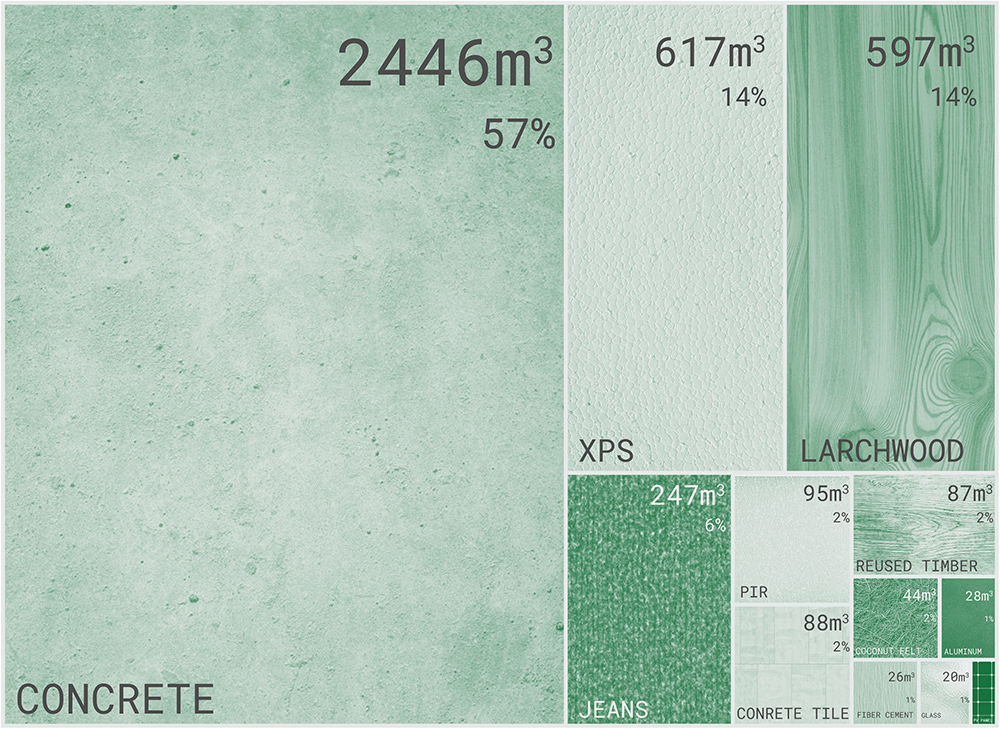

The salvaged materials of the project could be directly reused without further processing, meaning costs, effort, and energy were saved. When there was no reuse possibility, materials were collected and processed as needed in order to produce a viable construction material. The team got hold of reused fire-hose reels, cable ducts, and paving stones. The hardwood floor installed in the ground and first floor originated from a former monastery, the window frames are from demolished houses and some from a dissolved office, the roof terrace is partially from a villa and from a waste collection facility, the bar originated from a Dutch football club and the metal frames on the benches in the court are made from bicycles that were fished out of the canals in Amsterdam. 16.000 jeans were donated by the office workers as well as 2.500kg of former corporate clothes, an example of how invested the bank was in the construction. The textiles were recycled into fibre and used as insulation and acoustic wall panels.

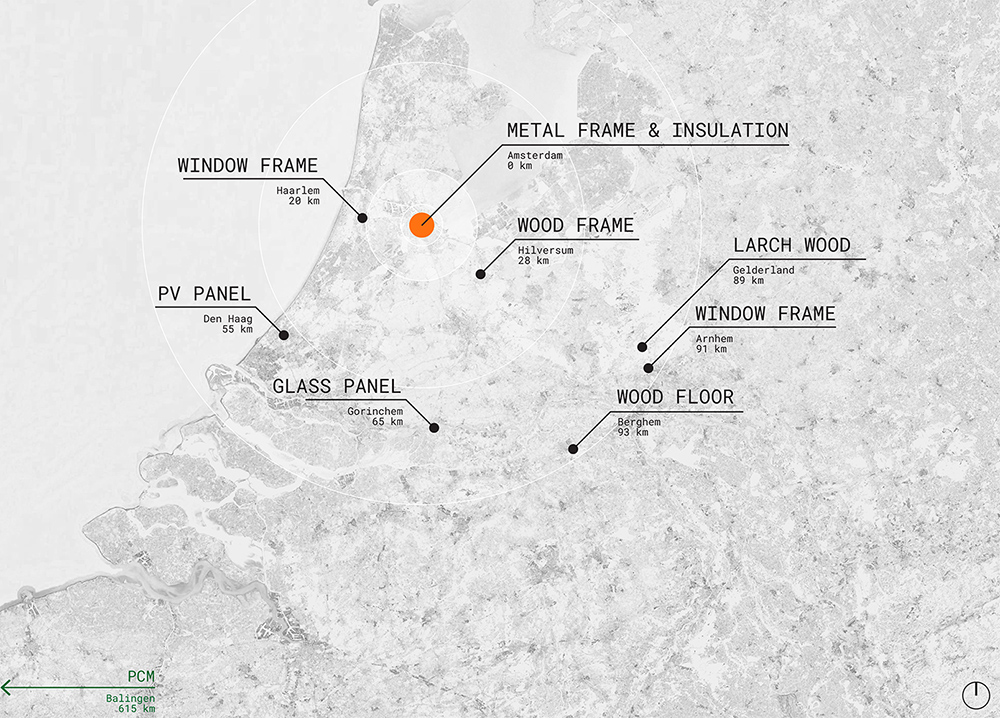

Material inventory and supply chains

Most materials used in the project come from nearby areas in the Netherlands, within a distance of 100km. Insulation is made of old jeans and metal frames from Amsterdam, window frames are from Haarlem and Arnhem, wood frames from Hilversum, glass panels from Gorinchem, and wood floors from Berghem. All of these are recycled building components from old or demolished buildings.