STROHUIS

Braunschweig, Germany

- Construction time

- 2015-2016

- Building type

- New built

- Client

- Private

- Architect

- CHRITH architects

- Project Partners

- Zimmerei Holzwerk Bohlmann & Brandes (wood construction), Baustroh GmbH (advice & licensing of straw construction)

- Size

- 189m2

- Use

- Housing

- Website

- Link ↗

- Banner image

- CHRITH Architects

General description

Strohuis is located in Braunschweig (Germany) and was planned by CHRITH, an architectural office based in the Netherlands. From the very beginning, the client wanted to construct a building with the smallest possible ecological footprint. This resulted in an increased cost of 10-20% compared to an average single-family house. Still, the project with a net floor area of 189m2 is an outstanding example of cost-effective as well as resource-saving architecture in rural areas. It shows the simplicity of building with natural materials and their enormous potential for a shift in construction.

Introduction to Circularity

Except the foundation, almost all the materials used in Strohuis are bio-based. This fact made the planning process more time- and cost-intensive and a profound communication between the architect and all other parties involved was necessary. But this lowers the failure costs compared to a conventional building because it was planned in great detail. A network of farmers in combination with a certification company made the local value chain of straw as an insulation material possible. Another aspect is self-building: the clients participated in the construction by compressing the straw into prefabricated panels on site and also helped with the clay filling as part of the building’s envelope.

Practices

If you would scale the project, components were repeated and prefabrication became feasible, the building would definitely be able to compete with conventional construction.

Christina Eickmeier, CHRITH architects

There is no standardisation or precise characteristic values for straw, because the material has different characteristics in different regions. That is why the company Baustroh GmbH was founded in Germany. The company has built up a network of farmers in Germany who can press straw as a building material and provides certification. The certification process of a straw bale as insulation material is very simple. Only the density, the dimensions and the degree of dryness are important. For the Strohuis, a farmer in Verden, northern Germany, not far from the project delivered the straw. This farmer specialises in baling straw for buildings and is also Baustroh GmbH’s largest supplier. The way his business model works is that he creates a network of neighbouring farmers in his region and presses the straw for them in a standard size and density. In this way, a building material is created from a local network that could be sold throughout Germany or even in the EU.

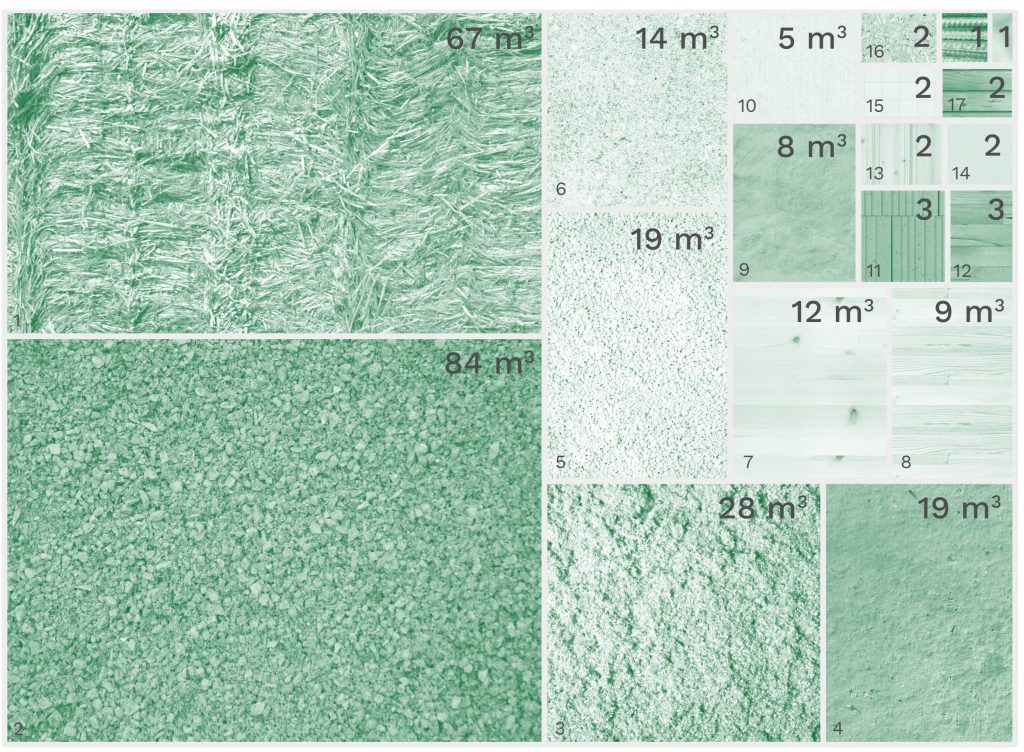

Material inventory and supply chains

When you look at other bio-based materials you realize, in most cases there are additives to the materials, which make the process of returning the material to nature impossible.

Christina Eickmeier, CHRITH architects

The construction materials for Strohhuis Braunschweig came from the nearest vicinity. For example, the gravel for the foundation was supplied by a local company that was in close contact with other relevant craftsmen. Thanks to Baustroh GmbH, a local supply chain for straw could be activated. The roof structure and other timber was supplied by Sägewerk Harz, which is located close to the site. The windows were imported from a Danish manufacturer. This project established a local network of materials that was characterised by sometimes only one layer of processing from sourcing to on-site construction.