K.118

Winterthur, Switzerland

- Time

- 2021

- Building type

- Roof extension

- Client

- Stiftung Abendrot

- Architect

- Baubüro in situ

- Project Partners

- Oberli Ingenieurbau AG (Bauingenieur), Josef Kolb AG, Stefan Signer (Holzbauingenieur)

- Size

- 1160 m2

- Use

- Mixed use (offices, studios)

- Website

- Link ↗

- Banner Image

- Georg Hubmann

General description

K.118 is the prize-winning three-story extension of an old warehouse in Winterthur, Switzerland. It was mainly built out of salvaged and natural materials with the goal to reuse as many materials as possible while keeping their reprocessing at a minimum. The architects managed to save 60% of Greenhouse Gas emissions and 500 tons of primary materials in comparison to a new building. The costs did not exceed the same building made from new materials.

It must become standard practice to assemble buildings in such a way that they can be taken apart again.

Barbara Buser, Baubüro in situ

Introduction to Circularity

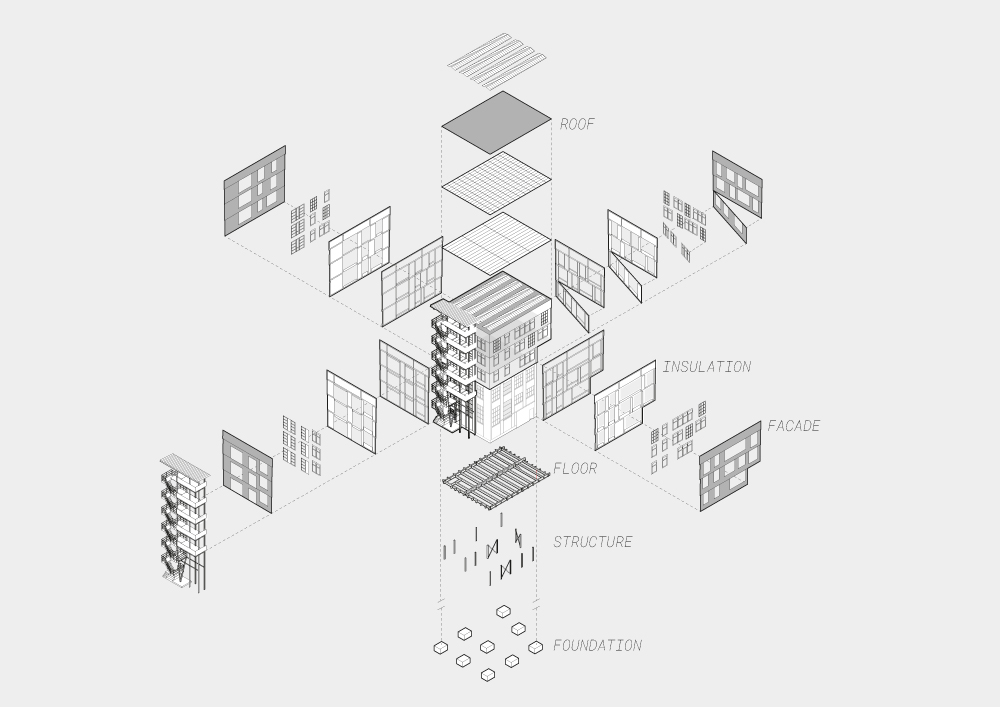

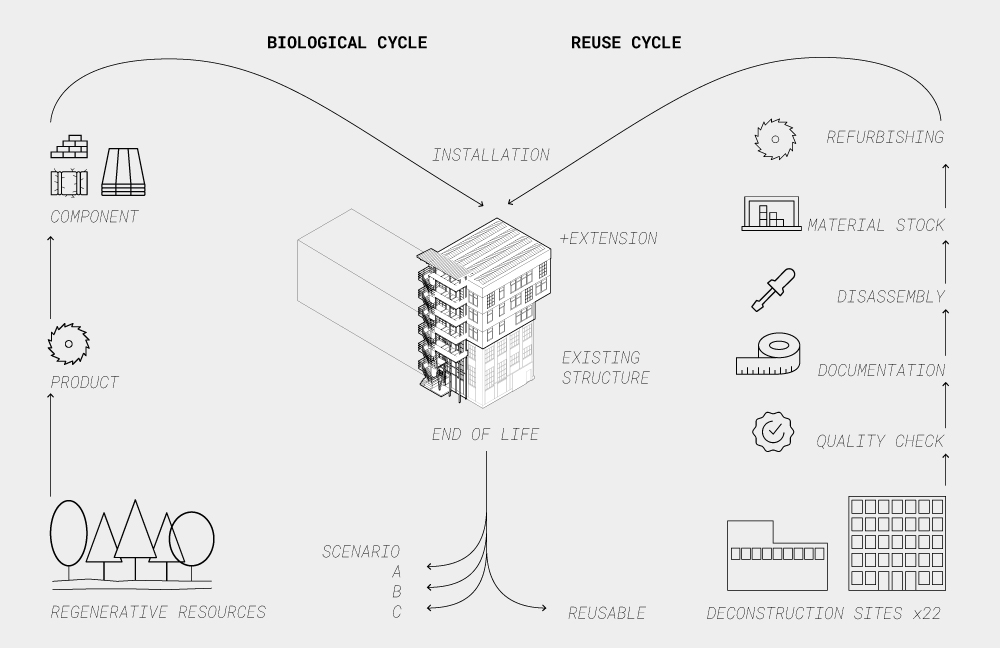

The project demonstrates the benefits of renovation and extension of existing building stock over demolition. K.118 was constructed using biobased and reused elements. Salvaged materials are used in their highest possible value. For example, in their second life, windows are again used as windows, doors as doors, steel structures as steel structures. Yet, the inexpensive reused materials require specialist manual labour to be re-installed properly, which in turn ensures sustainability for the local economy. Most of the new building materials are regenerative and have a small carbon-footprint (wood, straw, clay). These materials close their own loops, if they are not excessively mixed with glue. Ultimately, the building is designed to be taken apart again and allows for future modifications and reuse.

Practices

Once we have selected a component, we have to collect a lot of information about it so that we can use it appropriately. Unlike with new products, this data is usually not readily available.

Kerstin Müller, Baubüro in situ

The facade sheets originate from the Ziegler printing factory and their profiles are not identical: they have the same depth, but they vary in width. Thus, the sheets with different profiles cannot be joined together well. The problem was solved by letting the cladding in K.118 overlap. The originally two-storey steel structure is stacked on top of each other to form the framework of the three-storey extension. In plan, the rectangular structure overhangs the existing polygonal building. Instead of shortening, a cantilever was applied, which gives the building a distinctive form. The staircase, which was originally intended to be inside, was moved outside because the staircase and the steel structure have different floor heights. A few additional steps were necessary on the ground and first floor of the new building to adjust the levels to the dimensions of the staircase. In the case of K.118, the functions of the building were separated and thus modularly adaptable, making the spaces resilient to future changes.

K118 was constructed in a way that the components can be taken apart again. The construction remains simple, visible, and accessible. The components are screwed or clamped as far as possible and not glued or mortared. Existing structures can thus be replaced, repaired, or reused more easily. A building’s ability to adapt for future uses, to allow for material reuse and eventually to be disassembled are qualities the building industry should be aiming towards.

When it comes to upscaling the design approach of K. 118, the availability of suitable materials is pivotal. To establish the use of secondary materials in larger scale projects, the network around salvaged materials needs to be strengthened. Documentation of planned building demolitions and available building materials, as well as improved logistics are key factors to this transition.

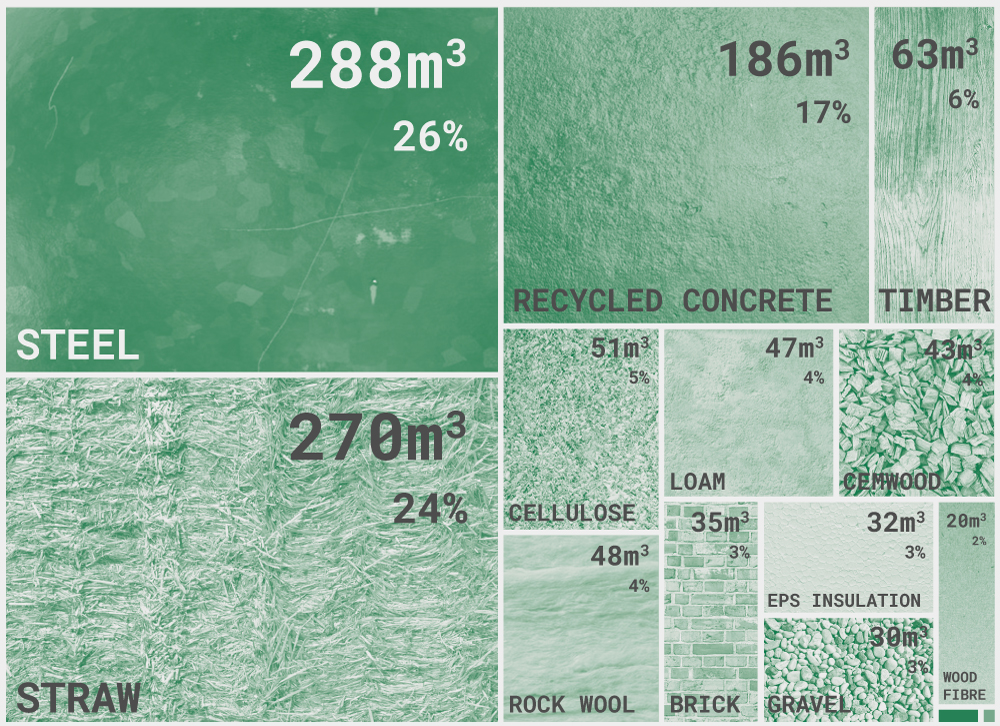

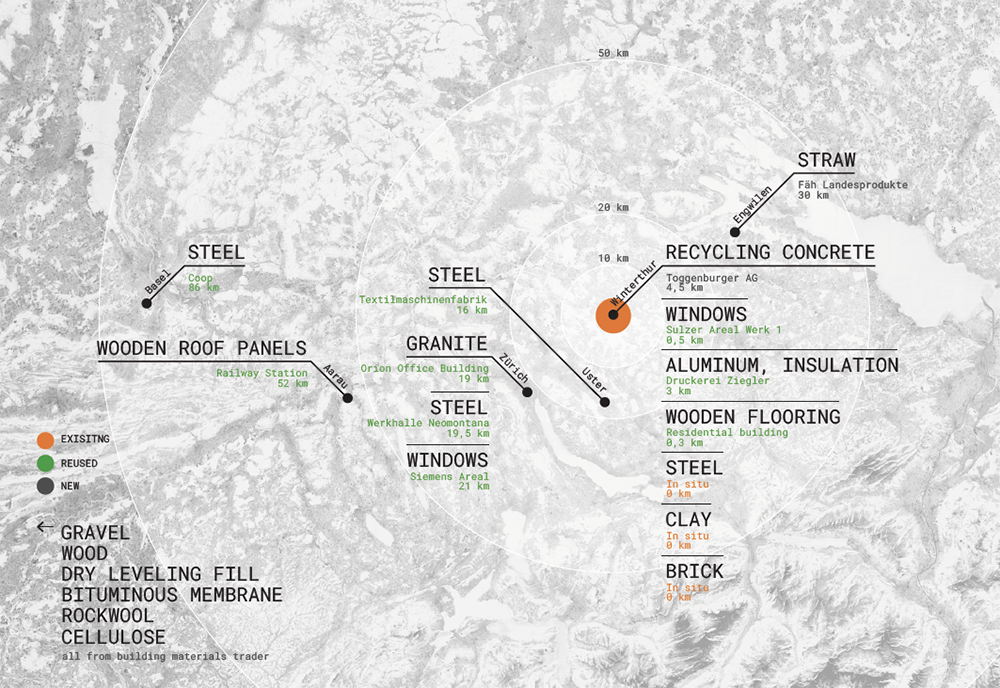

Material inventory and supply chains

The reused and existing components were mostly retrieved from demolition sites of industrial buildings and have a relatively small transportation impact, sourced within 100 km of the building. There were still some new materials used that travelled a longer distance but compared to the overall mass of the building, they were not significant.